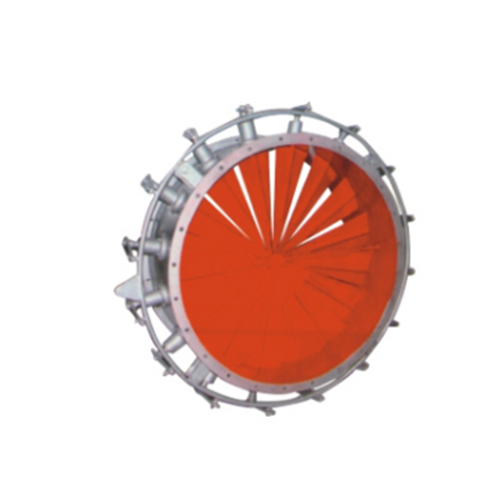

This valve is a new product of our factory and scientific research units for common development, and through the national identification,is a reliable equipment adjustment and opening and closing the air, flue gas,dust and gas and combustible gas,the valve can be matched with various execution combined mechanism into different perfomance of the valve,a plurality of blades,the noise is smallthe weight ilight,operating torque is small,large flow capacity,the operation is convenient,the price is cheap, especially for large diameter,high flow,low dropout applications,are widely used in metallurgy,mining, building materials,chemical industry,power plants and other industrial sectors.

Main dimensions and weight

| DN | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | |

| D | 640 | 755 | 860 | 975 | 1075 | 1175 | 1375 | 1575 | 1790 | 1990 | 2190 | 2405 | 2605 | 2805 | 3030 | 3230 | |

| D1 | 600 | 705 | 810 | 920 | 1020 | 1120 | 1320 | 1520 | 1730 | 1930 | 2130 | 2340 | 2540 | 2740 | 2960 | 3160 | |

| H | 890 | 1020 | 1110 | 1240 | 1340 | 1440 | 1660 | 1860 | 2060 | 2260 | 2500 | 2700 | 2900 | 3100 | 3330 | 3530 | |

| n-d | 20-22 | 20-26 | 24-26 | 24-30 | 28-30 | 32-30 | 36-30 | 40-30 | 44-30 | 48-30 | 52-33 | 56-33 | 60-33 | 64-36 | 68-36 | ||

| L | 300 | 350 | 400 | 500 | |||||||||||||

| b | 18 | 20 | 24 | 28 | |||||||||||||

| 片数Piece number | 3 | 5 | 7 | 9 | 11 | 15 | |||||||||||

| 重量(kg) Weight | 196 | 210 | 230 | 350 | 490 | 560 | 620 | 810 | 1010 | 1600 | 2050 | 2300 | 2500 | 2900 | 3100 | 3400 | |

| ZKJWdy | L1 | 1100 | 1210 | 1380 | 1480 | 1580 | 1675 | 1895 | 2145 | 2345 | 2545 | 2745 | 3125 | 3325 | 3525 | 3740 | 3940 |

| 电动 | ZKJ-210 | ZKJ-310 | ZKJ-410 | ZKJ-510 | ZKJ-610 | ZKJ-710 | |||||||||||

| Electric | |||||||||||||||||

| ZDTWdy | L1 | 970 | 1080 | 1220 | 1320 | 1530 | 1630 | 1840 | 2065 | 2270 | 2465 | 2680 | 2965 | 3165 | 3365 | 3565 | 3765 |

| 电动推杆 Electric push rod | DTII10020M | DTII10040M | DTII30050M | DTII50050M | DTII100060M | ||||||||||||

| SWdy | L1 | 900 | 1000 | 1150 | 1200 | 1410 | 1510 | 1710 | 1940 | 2145 | 2345 | 2545 | 2845 | 3000 | 3200 | 3400 | 3600 |

| 手动 Manual | S-01 | S-02 | S-03 | S-04 | S-05 | S-06 | |||||||||||

Round multi leaf butterfly valve: Complete Technical Guide

The round multi leaf butterfly valve is a specialized air control device widely used in HVAC systems, dust removal units, industrial exhaust pipelines, and environmental protection equipment. Unlike single-disc butterfly valves, this valve features multiple adjustable blades (or leaves) arranged within a circular housing, enabling precise airflow regulation and stable performance.

This article explores the design concept, performance testing, quality inspection requirements, and troubleshooting methods for round multi leaf butterfly valves. By the end, engineers, procurement managers, and operators will gain a clear understanding of why these valves are critical in industrial ventilation systems and how to maximize their service life.

The round multi leaf butterfly valve is designed with multiple blades connected to a central shaft or linkage mechanism. Each blade rotates simultaneously, allowing uniform airflow adjustment across the valve cross-section.

Key design features include:

Circular frame: Provides structural integrity and seamless connection with ventilation ducts.

Multiple blades (leaves): Typically 2–10 depending on valve size, allowing fine-tuned airflow control.

Linkage mechanism: Ensures synchronous movement of blades for precise regulation.

Sealing options: Rubber, silicone, or metal seals depending on application.

Efficient airflow regulation with minimal resistance.

Uniform distribution of air volume across large ducts.

Durability under continuous operation in industrial environments.

Easy operation through manual, electric, or pneumatic actuators.

Carbon steel – for general ventilation applications.

Stainless steel – for corrosion-resistant and cleanroom environments.

Aluminum alloy – for lightweight HVAC systems.

Before delivery, round multi leaf butterfly valves undergo strict performance testing to ensure compliance with industrial standards.

| Test Item | Purpose | Acceptance Standard |

|---|---|---|

| Airflow resistance test | Measures pressure loss across the valve | Should remain within specified low resistance range |

| Opening/closing torque test | Ensures smooth blade movement | Operation must be smooth without jamming |

| Leakage test | Checks sealing performance | Air leakage rate ≤ industry standard |

| Strength test | Validates mechanical durability | No deformation under rated pressure |

| Endurance test | Evaluates long-term operational stability | Minimum 5,000 open-close cycles without failure |

Wind tunnel test: Simulates airflow under different duct conditions.

Pressure chamber test: Evaluates sealing and leakage resistance.

Cycle testing: Automated open/close operations to simulate long-term use.

To ensure product reliability, every valve is accompanied by a quality inspection report.

| Inspection Aspect | Method of Inspection | Frequency |

|---|---|---|

| Dimensional accuracy | Caliper and gauge measurement | 100% inspection |

| Surface treatment quality | Visual inspection, coating test | Random sampling |

| Blade synchronization | Operational test | 100% inspection |

| Sealing performance | Airflow/pressure leakage test | 100% inspection |

| Material certification | Supplier test certificates | Per batch |

Material certificates confirming steel grade or alloy.

Performance test reports including airflow, leakage, and endurance results.

Compliance certificates (ISO, CE, or industry-specific standards).

Final inspection checklist signed by QA engineers.

Such thorough documentation provides confidence for international buyers and ensures compliance with export standards.

Even with robust design, long-term operation may lead to common issues. A proper troubleshooting guide helps maintain performance and extend lifespan.

| Issue | Possible Cause | Repair Method |

|---|---|---|

| Uneven blade movement | Linkage wear or misalignment | Adjust linkage, replace worn components |

| Excessive air leakage | Worn seals or improper flange connection | Replace seals, check and re-tighten flange bolts |

| Difficult opening/closing | Shaft corrosion or debris accumulation | Clean shaft, lubricate bearings, replace parts |

| Noise or vibration | Loose blades or excessive airflow speed | Tighten blade connections, adjust airflow settings |

| Actuator malfunction | Electrical or pneumatic failure | Inspect actuator, replace damaged control units |

Lubrication: Apply non-corrosive grease to shafts and linkages every 6 months.

Cleaning: Remove dust accumulation inside the valve regularly.

Seal replacement: Inspect and replace sealing materials annually or as needed.

Fastener check: Ensure bolts, nuts, and blade connections are tight.

Functional test: Operate the valve periodically to prevent stiffness.

Precise airflow control with multiple adjustable blades.

Energy efficiency due to low resistance design.

Versatility for HVAC, metallurgy, chemical, and dust removal applications.

Durable construction suitable for harsh industrial environments.

Ease of integration with manual, electric, or pneumatic actuators.

The round multi leaf butterfly valve is an essential component for modern ventilation and industrial air-handling systems. Its multi-blade design ensures precise control, stability, and efficiency across large ducts and heavy-duty applications.

By adhering to proper design principles, performance testing, quality inspection standards, and preventive maintenance practices, operators can significantly extend the valve’s service life and ensure reliable operation.

For procurement and engineering projects, selecting a high-quality valve backed by detailed inspection reports is the best way to ensure safety, compliance, and long-term performance in HVAC, chemical, and industrial ventilation systems.

This website uses cookies to ensure you get the best experience on our website.