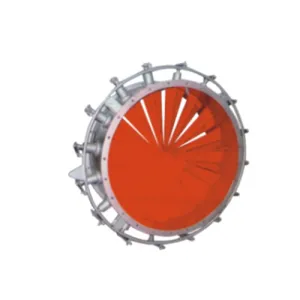

Industrial multi leaf butterfly valve for ventilation

Industrial Multi-Leaf Butterfly Valve for Ventilation Systems An industrial multi-leaf butterfly valve is a specialized airflow control device designed for large-scale ventilation and air handling systems. It is commonly used in HVAC (Heating, Ventilation, and Air Conditioning) applications, industrial exhaust systems, and process ventilation where precise regulation of airflow is required. The valve consists of multiple blades (or leaves) arranged in a circular frame, which rotate synchronously to modulate or shut off airflow efficiently. Design and Construction The multi-leaf butterfly valve is engineered for durability and high performance in demanding environments. The blades are typically made from lightweight yet robust materials such as aluminum, galvanized steel, or stainless steel, depending on the application’s corrosion resistance and temperature requirements. Each blade is mounted on a central spindle and connected via a linkage mechanism, ensuring uniform movement when actuated. The valve frame is designed to fit standard ductwork, with flanged or wafer-style connections for easy installation. Sealing elements, such as EPDM or silicone gaskets, are incorporated to ensure airtight closure when the valve is fully shut, minimizing leakage and improving energy efficiency. Operation and Control Multi-leaf butterfly valves can be operated manually, pneumatically, or electrically, depending on the system’s needs. Manual versions use hand levers or gear operators for simple adjustments, while automated actuators (electric or pneumatic) allow for remote control and integration with building management systems (BMS). The synchronized movement of the blades ensures smooth and precise airflow modulation, making them ideal for applications requiring variable air volume (VAV) control. Applications These valves are widely used in: - HVAC Systems: Regulating airflow in commercial and industrial buildings. - Industrial Ventilation: Controlling exhaust gases, dust, and fumes in manufacturing plants. - Fire and Smoke Management: Acting as dampers in smoke extraction systems to enhance safety. - Power Plants and Petrochemical Facilities: Handling high-temperature or corrosive air streams. Advantages - High Flow Efficiency: The multi-blade design minimizes pressure drop, optimizing system performance. - Compact and Lightweight: Easier to install compared to single large-diameter dampers. - Reliable Sealing: Tight shut-off capability reduces energy loss and improves system control. - Low Maintenance: Robust construction ensures long service life with minimal upkeep. Conclusion The industrial multi-leaf butterfly valve is a versatile and efficient solution for ventilation and air control systems. Its synchronized blade operation, durable construction, and adaptability to various control methods make it a preferred choice for engineers and system designers seeking reliable airflow management in industrial and commercial environments.

Products

Category:

-

Round multi leaf butterfly valve

Category: Metallurgical valve seriesBrowse number: 91Number:Release time: 2025-09-22 08:35:09The Round Multi Leaf Butterfly Valve is a specialized airflow control device designed for ventilation, dust removal, and industrial exhaust systems. Featuring multiple adjustable blades within a circular housing, it allows precise regulation of air volume while maintaining low resistance and stable operation. With its robust structure, easy installation, and long service life, the round multi leaf butterfly valve is widely used in HVAC ducts, environmental protection equipment, metallurgy, chemical plants, and power stations. It ensures efficient airflow management, reliable sealing, and energy savings for large-scale industrial applications.

News

Category:

No search results found!

Case

Category:

No search results found!

Video

Category:

No search results found!

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!

Phone

Phone