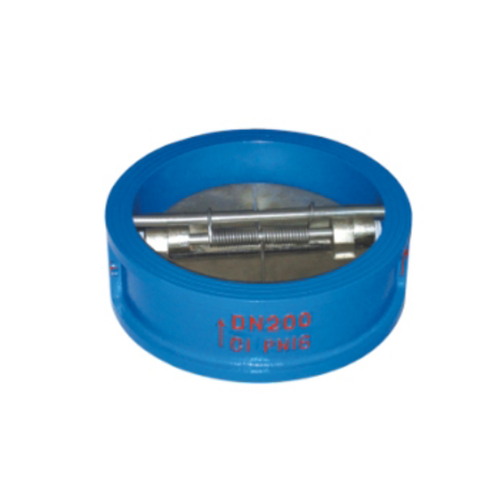

Wafer butterfly check valve a save-energv product,is manufactured based on the foreign advanced technology and in accordance with relative international standards.This product is featured by excellentretaining perfomance,high safety and reliability and low flow resitance.it is suitable for systems in the industries of perochemical,food processing, medicine,textile,paper-making,water supply and drainage, metallurgy,energy and lightindustry etc used as a check valve in one way.

Technical data

公称通径DN(mm) Nominal diameter | 50(2")~700(28") | 50(2")~450(18") | |

公称压力PN(MPa) Nominal pressure |

1.0 |

1.6 | |

试验压力 (MPa) Testing pressure |

壳体Shell |

1.5 |

2.4 |

密封Sealing |

1.1 |

1.76 | |

适用温度℃ Working temperature |

-15~+150 | ||

适用介质 Suitable mediums | 淡水、污水、空气、蒸气、食品、药品、各种油类、酸类等 Fresh water,sewage,air,steam,food,medicine,oils,acids,etc | ||

Meterial of main parts

阀体 Body | 阀 板 Disc | 转 轴 Stem | 橡胶座 Rubber gasket | 弹簧 Spring | ||||

材料名称 Name | 代号 Code | 材料名称 Name | 代号 Code | 材料名称 Name | 材料名称 Name | 代号 Code | 适用温度℃ Working temp | 材料名称 Name |

灰铸铁 Cast Iron

球墨铸铁 Ductile Iron

碳钢 Carbon steel 不锈钢 Stainless steel |

Z

Q

C

P | 电镀球墨 铸铁 Plated ductile Iron 铝青铜 Aluminum bronze ZG1Cr13Ni9T 不锈钢 Stainless steel C F 8 M 不 锈 钢 Stainless steel C F 8 M 不 锈 钢 Stainless steel |

1

2

5

7 |

不锈钢 Stainless steel |

乙丙橡胶 EPDM

氯丁橡胶 Neoprene

丁腈橡胶 NBR

氯丁橡胶 Neoprene |

X3

X4

X5

X7 | -46~+121 短时 Intemittence -50~+150 -29~+99 短时 Intemittence -35~+113 -23~+82 短时 Intemittence -23~+93 -23~+150 |

不锈钢 Stainless steel |

Main dimensions and weight

阀体 Body | 阀 板 Disc | 转 轴 Stem | 橡胶座 Rubber gasket | 弹簧 Spring | ||||

材料名称 Name | 代号 Code | 材料名称 Name | 代号 Code | 材料名称 Name | 材料名称 Name | 代号 Code | 适用温度℃ Working temp | 材料名称 Name |

灰铸铁 Cast Iron

球墨铸铁 Ductile Iron

碳钢 Carbon steel 不锈钢 Stainless steel |

Z

Q

C

P | 电镀球墨 铸铁 Plated ductile Iron 铝青铜 Aluminum bronze ZG1Cr13Ni9T 不锈钢 Stainless steel C F 8 M 不 锈 钢 Stainless steel C F 8 M 不 锈 钢 Stainless steel |

1

2

5

7 |

不锈钢 Stainless steel |

乙丙橡胶 EPDM

氯丁橡胶 Neoprene

丁腈橡胶 NBR

氯丁橡胶 Neoprene |

X3

X4

X5

X7 | -46~+121 短时 Intemittence -50~+150 -29~+99 短时 Intemittence -35~+113 -23~+82 短时 Intemittence -23~+93 -23~+150 |

不锈钢 Stainless steel |

Main dimensions and weight

DN |

D |

D1 |

D2 |

L |

R |

t | 重量 Weight (kg) | |

mm | inch | |||||||

50 | 2" | 107 | 65 | 43.3 | 43 | 28.2 | 19 | 1.5 |

65 | 2.5" | 127 | 80 | 60.2 | 46 | 36.1 | 20 | 2.4 |

80 | 3" | 142 | 94 | 66.4 | 64 | 43.4 | 28 | 3.6 |

100 | 4" | 162 | 117 | 90.8 | 64 | 52.8 | 27 | 5.7 |

125 | 5" | 192 | 145 | 116.9 | 70 | 65.7 | 30 | 7.3 |

150 | 6" | 218 | 170 | 144.6 | 76 | 78.6 | 31 | 9.0 |

200 | 8" | 273 | 224 | 198.2 | 89 | 104.4 | 33 | 17 |

250 | 10" | 328 | 265 | 233.7 | 114 | 127 | 50 | 26 |

300 | 12" | 378 | 310 | 283.9 | 114 | 148.3 | 43 | 42 |

350 | 14" | 438 | 360 | 332.9 | 127 | 172.4 | 45 | 55 |

400 | 16" | 489 | 410 | 381.0 | 140 | 197.4 | 52 | 75 |

450 | 18" | 55 | 450 | 419.9 | 152 | 217.8 | 58 | 107 |

500 | 20" | 594 | 505 | 467.8 | 152 | 241 | 58 | 111 |

600 | 24" | 690 | 624 | 572.6 | 178 | 295.4 | 73 | 172 |

700 | 28" | 800 | 720 | 680 | 229 | 354 | 98 | 219 |

Wafer Butterfly Check Valve – Complete Product Guide

The Wafer Butterfly Check Valve is a versatile industrial valve designed to prevent backflow and ensure unidirectional fluid flow in pipelines. Its compact wafer-style design enables installation between standard flanges, making it ideal for space-constrained applications. Featuring high-quality stainless steel, carbon steel, or ductile iron construction with resilient rubber or metal seats, the valve delivers long-lasting performance, corrosion resistance, and reliable sealing.

Widely applied in water treatment, HVAC systems, chemical processing, and industrial fluid control, the wafer butterfly check valve provides efficient operation, minimal maintenance, and superior flow control under varying pressure conditions.

Wafer-Style Compact Design: Fits snugly between flanges for easy installation.

Backflow Prevention: Ensures unidirectional flow, protecting pumps and pipeline systems.

Durable Materials: Stainless steel, carbon steel, or ductile iron body with resilient seats.

Low Maintenance: Simple structure reduces wear and operational costs.

Versatile Applications: Suitable for water, oil, chemicals, and gases.

High Performance: Reliable sealing, minimal leakage, and smooth operation.

| Feature | Specification / Range |

|---|---|

| Body Material | Stainless Steel 304/316, Carbon Steel, Ductile Iron |

| Disc Material | Stainless Steel, Carbon Steel |

| Seat Material | EPDM, NBR, PTFE, or Metal-to-Metal |

| Pressure Rating | PN10 – PN40 / ANSI Class 150 – 300 |

| Temperature Range | -20°C to 180°C (-4°F to 356°F) |

| End Connection | Wafer (Between Flanges) |

| Operation Type | Manual, Pneumatic, or Electric Actuation |

| Suitable Medium | Water, Oil, Gas, Chemical Fluids |

To enhance performance and usability, the wafer butterfly check valve can be equipped with various accessories:

Actuators: Electric or pneumatic for automated operation.

Position Indicators: Shows valve open/closed status for monitoring.

Mounting Kits: Ensures proper alignment and secure actuator installation.

Stem Extensions: Facilitates operation in hard-to-reach locations or insulated pipelines.

Insulation Jackets: Provides thermal protection and environmental safety.

| Accessory | Purpose |

|---|---|

| Electric Actuator | Remote or automated valve control |

| Pneumatic Actuator | Quick, reliable operation |

| Position Indicator | Accurate feedback for valve status |

| Mounting Kit | Simplifies actuator integration |

| Stem Extension | Allows operation in inaccessible areas |

| Insulation Jacket | Thermal and environmental protection |

Proper installation ensures optimal performance, safety, and long service life:

Pre-Installation Check: Verify valve compatibility with pipeline size, pressure rating, and fluid type.

Orientation: Install the valve between flanges, observing the flow direction arrow.

Alignment: Ensure pipeline flanges are properly aligned to prevent stress on the valve body.

Torque Application: Apply manufacturer-recommended torque to flange bolts to avoid leaks.

Actuator Integration: Follow wiring and air supply instructions for pneumatic or electric actuators.

Pressure Testing: Test the system post-installation to confirm leak-free operation.

(Include schematic showing wafer-style body, disc, seat, stem, flanges, and optional actuator.)

Opening and Closing: The valve operates automatically when fluid flows in the correct direction; no manual intervention is usually required.

Flow Control: For actuated versions, gradually open or close to prevent water hammer or pressure surges.

Safety Precautions: Always depressurize the system before performing maintenance or inspection.

Monitoring: Use position indicators to ensure the valve is functioning correctly and maintaining proper flow.

Regular maintenance is key for long-term reliable performance:

| Task | Frequency (Normal Service) | Frequency (Heavy-Duty/Corrosive Fluids) |

|---|---|---|

| Visual Inspection | Weekly | Daily |

| Functional Testing | Monthly | Weekly |

| Seat & Seal Inspection | Every 6 months | Every 3 months |

| Lubrication of Moving Parts | Every 6 months | Every 3 months |

| Complete Overhaul | Every 12–18 months | Every 6–12 months |

Inspect disc, seat, and body for wear, corrosion, or damage.

Replace worn seals or seats immediately to maintain leak-free operation.

Clean the interior valve surfaces to remove debris or chemical deposits.

Lubricate stems or actuator components as per manufacturer recommendations.

Periodically test the valve for proper backflow prevention and smooth operation.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Leakage at valve seat or body | Worn or damaged seat, misalignment | Replace seat, realign valve |

| Valve disc not moving freely | Debris, corrosion, or misalignment | Clean valve interior, lubricate, realign |

| Backflow occurs | Faulty seat or disc | Replace seat or disc |

| Excessive noise or vibration | High flow velocity or water hammer | Reduce flow rate, install dampeners |

| Actuator malfunction | Electrical/air supply issues | Inspect and repair actuator wiring or air lines |

The Wafer Butterfly Check Valve is ideal for industrial and municipal applications where backflow prevention, compact design, and low maintenance are essential:

Water Treatment Plants: Ensures unidirectional water flow, preventing contamination.

HVAC Systems: Protects pumps and reduces energy losses.

Chemical Processing: Handles corrosive or abrasive fluids safely.

Industrial Fluid Control: Suitable for oil, gas, and other liquids in pipelines.

| Industry | Application Scenario | Benefits |

|---|---|---|

| Water Treatment | Clean water and wastewater pipelines | Prevents backflow, minimal maintenance |

| HVAC Systems | Pump protection and flow control | Reduces energy loss, protects equipment |

| Chemical Processing | Aggressive chemical pipelines | Corrosion-resistant, leak-free operation |

| Industrial Manufacturing | Oil, gas, or liquid distribution | Compact, reliable, and durable |

The Wafer Butterfly Check Valve offers efficient backflow prevention, compact wafer-style design, and reliable operation across a variety of industrial applications. By following proper installation, accessory integration, and routine maintenance, this valve ensures long-term performance, leak-free operation, and minimal downtime. Its durable materials, low-maintenance design, and versatile applicability make it an ideal solution for water treatment, HVAC, chemical processing, and industrial fluid systems.

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.