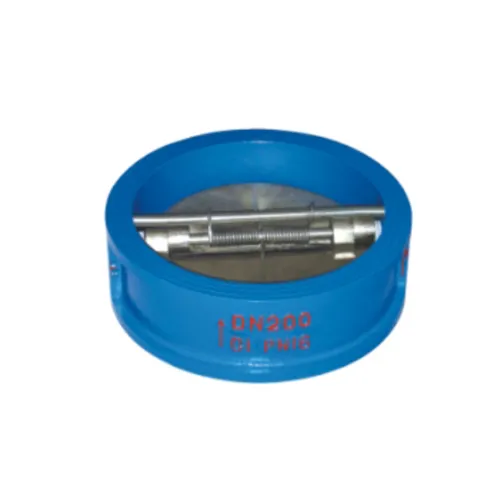

Features

1.Double valve butterfly valve on the folder structure length of the short length of its struc-ture,only the traditional flange checkvalve 1/4 to 1/8;

2.Small size,light weight,its weight is only the traditional flange check valve 1/4 to 1/20;

3.wafer butterfly valve double valve valve valve quickly,the water hammer pressure is small;

4.Horizontal pipe and vertical pipe can be used,easy installation;

5.Wafer butterfly valve double valve flow smooth,fluid resistance is small;

6.Movement sensitive,good sealing performance;

7.On the folder double valve butterfly valve disc travel is short,the impact force is small;

8.The overall structure simple and compact,attractive appearance;

9.Long life and high reliability.

Technical data

零件名称Part name | 材 料 M e t e r i a l | |||||||

阀体Valve body | WCB | ZG1Gr-18Ni9TI | CF8 | CF3 | ZG1Gr-18 Ni12Mo2TI | CF8M | CF3M | |

阀瓣、阀座、弹簧 Valve disc,Valve seat,spring |

2Cr13 |

1Gr18Ni9Ti | 0Gr18Ni9(304) | 00Gr18Ni10 (304L) | 1Gr18Ni- 12Mo2T | 0Gr18Ni12- Mo2(310) | 00Gr17Ni14- Mo2(316L) | |

适用介质Suitable Mediums | 水、蒸汽、油品 Water,steam,oil | 硝酸等腐蚀性介质 Nitric acid and other corrosive media | 强氧化性介质 Chronic Effects | 醋酸等腐蚀性介质 Acetic acid and other corrosive media | 尿素等腐蚀性介质 Urea and other corrosive media | |||

适用温度℃Working Temperature |

≤450 |

≤200 | ||||||

Main dimensions and weight

PN (MPa) | DN (mm) |

L |

D |

D3 |

D2 | 重量(kg) Weight | 螺栓孔中心圆直径 Center bolt hole circle diameter D1 | 螺栓数量 bolts number | 螺栓直径 Bolt diameter d | 螺栓长度L1 Bolt length L1 |

1.0 | 50 | 60 | 108 | 56 | 51 | 2 | 125 | 4 | M16 | 150 |

65 | 67 | 128 | 73 | 65 | 3 | 145 | 4 | M16 | 155 | |

80 | 73 | 142 | 88 | 80 | 4 | 160 | 8 | M16 | 160 | |

100 | 73 | 162 | 108 | 102 | 6 | 180 | 8 | M16 | 165 | |

125 | 86 | 192 | 132 | 127 | 8 | 210 | 8 | M16 | 180 | |

150 | 98 | 218 | 160 | 152 | 13 | 240 | 8 | M20 | 205 | |

200 | 127 | 273 | 210 | 203 | 24 | 295 | 8 | M20 | 235 | |

250 | 146 | 328 | 266 | 254 | 37 | 350 | 12 | M20 | 255 | |

300 | 181 | 378 | 310 | 305 | 50 | 400 | 12 | M20 | 290 | |

350 | 184 | 438 | 355 | 350 | 76 | 460 | 16 | M20 | 295 | |

400 | 191 | 489 | 405 | 400 | 110 | 515 | 16 | M24 | 310 | |

450 | 203 | 539 | 455 | 450 | 135 | 565 | 20 | M24 | 325 | |

500 | 219 | 594 | 505 | 500 | 158 | 620 | 20 | M24 | 345 | |

600 | 222 | 696 | 605 | 600 | 320 | 725 | 20 | M27 | 355 | |

700 | 305 | 811 | 700 | 695 | 380 | 840 | 24 | M27 | 440 | |

800 | 305 | 918 | 800 | 796 | 560 | 950 | 24 | M30 | 450 | |

900 | 368 | 1018 | 903 | 898 | 640 | 1050 | 28 | M30 | 520 | |

1000 | 432 | 1124 | 1055 | 1050 | 900 | 1160 | 28 | M33 | 590 | |

1200 | 524 | 1340 | 1205 | 1200 | 1400 | 1380 | 32 | M36 | 695 |

Stainless Steel Butterfly Check Valve – Comprehensive Product Guide

The Stainless Steel Butterfly Check Valve is a high-performance industrial valve engineered to prevent backflow and ensure unidirectional flow in pipelines. Constructed from premium stainless steel, this valve provides corrosion resistance, durability, and long-term reliability, making it ideal for demanding environments in water treatment, chemical processing, HVAC systems, and industrial fluid control.

Its compact butterfly design allows for space-efficient installation between flanges, while offering minimal maintenance requirements, smooth operation, and robust sealing. This guide covers safety instructions, installation procedures, upgrade options, and warranty policies, ensuring optimal performance and longevity.

High-Quality Stainless Steel: Resistant to corrosion, oxidation, and high pressure.

Backflow Prevention: Protects pumps and systems by ensuring unidirectional flow.

Compact Butterfly Design: Space-saving and suitable for wafer-style installation.

Low Maintenance: Simple construction reduces downtime and operational costs.

Wide Applications: Ideal for water, oil, gas, and chemical fluids.

Reliable Performance: Smooth operation with minimal leakage under varying pressures.

| Feature | Specification / Range |

|---|---|

| Body Material | Stainless Steel 304/316 |

| Disc Material | Stainless Steel, optionally coated |

| Seat Material | EPDM, NBR, PTFE, or Metal-to-Metal |

| Pressure Rating | PN10 – PN40 / ANSI Class 150 – 300 |

| Temperature Range | -20°C to 180°C (-4°F to 356°F) |

| End Connection | Wafer-style (between flanges) |

| Operation Type | Manual, Pneumatic, or Electric Actuation |

| Suitable Medium | Water, Oil, Gas, Chemical Fluids |

Operating the Stainless Steel Butterfly Check Valve safely is crucial to prevent accidents and ensure system integrity:

Depressurize Pipelines: Always release pressure before performing maintenance or inspection.

Avoid Excessive Torque: Use manufacturer-recommended torque values for flange bolts to prevent valve damage.

Proper Personal Protective Equipment (PPE): Use gloves, goggles, and protective clothing when handling chemicals or hot fluids.

Regular Inspection: Check for leaks, corrosion, or unusual vibration to avoid operational hazards.

Follow Flow Direction: Ensure correct installation according to the flow arrow on the valve body.

Proper installation is essential for optimal performance and long service life:

Pre-Installation Check: Confirm valve size, pressure rating, and compatibility with pipeline medium.

Orientation: Install valve between flanges, ensuring the flow direction aligns with the system.

Alignment: Avoid misaligned flanges to prevent stress on the valve body.

Torque Application: Apply correct torque evenly on all flange bolts.

Actuator Installation: For actuated valves, follow electrical or pneumatic connection guidelines.

Post-Installation Testing: Conduct pressure tests to verify leak-free operation.

(Include schematic showing wafer-style body, disc, seat, stem, and optional actuator.)

To enhance functionality and system integration, the Stainless Steel Butterfly Check Valve can be upgraded with:

Actuators: Electric or pneumatic for automated flow control.

Position Indicators: Provide visual confirmation of valve status.

Remote Monitoring Systems: Enable real-time tracking of valve operation.

Corrosion-Resistant Coatings: For highly aggressive chemical environments.

Extended Stem and Insulation Jackets: Useful for pipelines in hard-to-reach or insulated areas.

| Upgrade Option | Purpose |

|---|---|

| Electric Actuator | Automated valve operation |

| Pneumatic Actuator | Rapid, precise actuation |

| Position Indicator | Visual flow status confirmation |

| Remote Monitoring | Real-time operational tracking |

| Corrosion-Resistant Coating | Enhanced chemical resistance |

| Extended Stem & Insulation | Accessibility and thermal protection |

Opening and Closing: The valve opens automatically with forward flow; closes when flow reverses.

Actuated Versions: Gradually operate actuators to prevent water hammer or pressure surges.

Monitoring: Position indicators help verify correct operation.

Routine Checks: Regularly inspect for leaks, corrosion, and smooth disc movement.

Routine maintenance ensures longevity and reliable performance.

| Task | Frequency (Normal Use) | Frequency (Heavy/Corrosive Use) |

|---|---|---|

| Visual Inspection | Weekly | Daily |

| Functional Testing | Monthly | Weekly |

| Seat & Seal Inspection | Every 6 months | Every 3 months |

| Lubrication of Moving Parts | Every 6 months | Every 3 months |

| Complete Overhaul | Every 12–18 months | Every 6–12 months |

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Leakage at valve seat or body | Worn seat, misalignment | Replace seat, realign valve |

| Disc not moving freely | Debris, corrosion, or misalignment | Clean valve, lubricate, realign |

| Backflow occurs | Faulty disc or seat | Replace disc or seat |

| Excessive noise | High flow velocity or water hammer | Reduce flow, install dampeners |

| Actuator malfunction | Electrical or air supply issue | Inspect actuator, repair connections |

The Stainless Steel Butterfly Check Valve comes with a manufacturer-backed warranty, ensuring quality and peace of mind:

Warranty Coverage: Typically 12–24 months against material defects or manufacturing faults.

Quality Control: Each valve undergoes pressure testing, leak testing, and dimensional verification before shipment.

Replacement Policy: Defective components or valves are replaced under warranty terms.

Support Services: Technical guidance for installation, maintenance, and troubleshooting.

The valve is widely used in industrial, municipal, and commercial applications requiring reliable backflow prevention:

Water Treatment Plants: Ensures clean water distribution and pump protection.

Chemical Processing: Handles aggressive fluids with corrosion-resistant materials.

HVAC Systems: Prevents reverse flow and reduces energy loss.

Oil & Gas Industry: Controls flow in pipelines and prevents contamination.

| Industry | Scenario | Benefits |

|---|---|---|

| Water Treatment | Pipelines for clean or wastewater | Prevents backflow, protects pumps |

| Chemical Industry | Corrosive fluid pipelines | Durable and leak-free operation |

| HVAC Systems | Cooling/heating water distribution | Energy-efficient, protects equipment |

| Oil & Gas | Transport of hydrocarbons | Reliable, corrosion-resistant, compact |

The Stainless Steel Butterfly Check Valve combines durability, reliability, and space-saving design for a wide range of industrial applications. Following proper installation, safety precautions, upgrades, and routine maintenance, this valve ensures efficient backflow prevention, long-term performance, and reduced operational costs. Its high-quality materials, versatile applications, and comprehensive warranty make it a preferred choice for industrial, commercial, and municipal fluid systems.

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.